So far in our Ultimate Guide to Card Stock, we have discussed the importance of sheet size and paper weight, as well as paper finishes and colors. In this installment of the Ultimate Guide, we’ll take a closer look at how to print on card stock, as well as outline four common finishing services: perforating, drilling, cutting, and scoring.

Printing on cardstock isn’t as simple as printing on a standard sheet of paper. Since cardstock is thicker, it requires additional care and consideration in order to avoid issues such as:

- Cracking when folding

- Cutting without tearing

- Warping or curvature during printing

- Roller marks

- Printer jams

Professional finishing services like perforating and scoring will help you avoid any problems with tearing and folding, but the easiest way to avoid other printing imperfections is to follow the specifications in your printer’s manual. Read on to learn more about printing on or finishing card stock.

Printing at Home

Not all at-home printers are equipped to handle every card stock weight. You will likely won’t run into any issues with thinner or lighter sheets of card stock like 65lb or 80lb, but you should always make sure you check your printer’s instruction manual for the weight range your machine can handle before you print. Some higher-end printers are capable of printing on upwards of 165 lb card stock, but once you start getting into heavier weights, you may encounter problems like jamming, curling, or roller marks.

Learn more about card stock weight in Part 2 of the Ultimate Guide to Card Stock.

Here are some tips for printing on cardstock at home:

- If you’re shopping for card stock to print on at home, make use of our Printer Compatibility filter to ensure you choose a sheet that will run properly through your printer.

- Always do a test run so you can see how well certain weight will print in your specific machine.

PRO TIP: Sample sheets are a good way try out card stock you aren’t familiar with without investing too much money. Choose up to five 8 ½ x 11 samples of any card stock for $3 per sheet. Samples ship free.

- After determining your printer’s weight range, shop for those specific weights.

- For thicker sheets, try hand-feeding the sheets one at a time.

- Bottom or front-feed trays and printers might damage cardstock over 80 lb. In these kinds of printers, the paper has to move through tight spaces in order to flip over inside the printer, which can cause your sheet to develop a permanent curvature. For this reason, it’s best to use a rear-feed or top-loading printer or tray. It’s also easier to hand-feed sheets of cardstock to these types of printers.

- Change your print settings to reflect what type of paper or media you are printing on. The specific type of card stock you are printing on may not be an option, but if you are having issues, try out some of the other settings for similar paper types. It might solve any jamming problems you may be having.

Printer Compatibility

Cardstocks are compatible with a variety of printers, but your printer’s exact capabilities will depend on its make and model. You’re most likely to print on one of these types of printers at home:

Print quality can also be impacted by the type of finish your card stock has. While a glossy finish can make colors pop, a matte finish is easier to read and makes text the star of the show.

Learn more about card stock finishes in Part 3 of the Ultimate Guide to Card Stock.

Commercial Printing

If you don’t like the results you’re getting at home or you want to print on a very thick card stock, consider taking your design to a professional printing company.

Professional printing houses have access to machines with greater capabilities than at-home printers, allowing them to print on a wider range of weights, finishes, and sizes.

The cost of ink, access to professional-grade equipment, and the expertise of your printer can help keep your project from running up an unreasonable bill and save you time and frustration. Commercial printing can also make your work look its best because printers often offer unique features such as:

- Letterpress

- Specialized inks and coatings

- Embossing or debossing

Paper Finishing Services

There are a number of finishing services available for card stock to ensure your creative projects look clean and professional. These services are available for paper as well, but they are especially important for card stock, which often requires special treatment due to its heavier weight. Because it’s thicker, card stock is more likely to crack or tear when folding and cutting. The heavier the card stock, the more likely it is that you will do damage without the proper tools. Utilizing professional finishing services can save you time and effort, especially with large runs.

The Paper Mill Store offers four main finishing services:

1. Cutting

Cutting makes sure you find the exact size card stock you need. If you’re looking for something outside the standard range of sheet sizes, cutting services can help trim off any excess card stock and create a product that suits your exact specifications.

Common/Ideal uses:

- Uncommon sheet sizes

- Custom dimensions

Choose a cutting-compatible card stock.

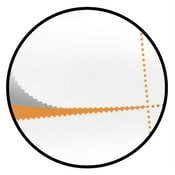

2. Scoring

Scoring helps cardstock to fold cleanly and quickly. Scoring is created by using a scoring tool to press an indent into the cardstock. This indent creates a crease that makes it easier to fold the sheet without cracking, making your cards, invitations, or folded designs look crisp and refined.

Common/Ideal uses:

- Cards

- Invitations

- Booklets

- Pamphlets & Brochures

- Place cards

Select a scoring-compatible card stock.

3. Perforating

Perforating adds a series of holes to your card stock, making it easy to quickly fold and tear off pieces in specified sizes or shapes.

Common/Ideal uses:

- Tickets

- Business cards

- Shelf-talkers

- Coupons

Pick out a perforating-compatible cardstock.

Visit our perforated paper shop.

4. Hole Punching

Drilling or hole punching adds clean circular holes to a sheet of card stock. These holes make it easy to quickly put together a document in a binder or presentation folder. Customizable widths and an adjustable number of holes make it easy to fit any binding application.

Common/Ideal uses:

- Handouts

- Booklets

- Informational packages

- Presentations

Shop our full selection of drilling-compatible cardstock.

Learn more about our paper finishing services.

Finishing Up

Printing or finishing card stock can be tricky if you don’t know how the weight of your sheet will affect the outcome. Sample pages and test runs are the best way to determine what will work best for your project and help you develop an understanding of the end-result. After all, you don’t want to invest a lot of time and money in a card stock selection only to discover it isn’t going to print out the way you want! Make sure you find something that will work for your printer and, when it doubt, don’t hesitate to reach out to the experts.

Contact us at (800) 790-TPMS (8767) or email cs@thepapermillstore.com.

Part 1: Introduction to Card Stock

Part 2: Paper Weights & Sheet Sizes

Part 3: Paper Finishes & Colors

Part 4: Printing & Finishing

Part 5: How and When to Use Card Stock