Carbonless paper might not make headlines, but for printers, office managers, and educators, it’s one of those behind-the-scenes essentials that keep daily operations running smoothly.

From invoices and order forms to lab reports and delivery slips, carbonless paper helps businesses stay organized without the need for messy carbon sheets or manual duplication.

But one question often arises: What’s the difference between reverse sequence and straight sequence carbonless paper, and which should you use?

Let’s explore how carbonless paper works, what sets these two sequence types apart, and how to choose the right option for your workflow.

What Is Carbonless Paper?

Before diving into sequence types, it helps to understand what carbonless paper actually is.

Developed in the 1950s as a cleaner, more efficient alternative to traditional carbon sheets, carbonless paper, often called NCR paper (for “No Carbon Required”), allows you to create instant duplicates or triplicates of a document. It’s a time-saver in industries where multiple copies are a must, such as shipping, accounting, healthcare, and field services.

By eliminating the need for separate carbon inserts, carbonless paper provides clearer copies, reduces mess, and offers a more sustainable, user-friendly solution.

How Does Carbonless Paper Work?

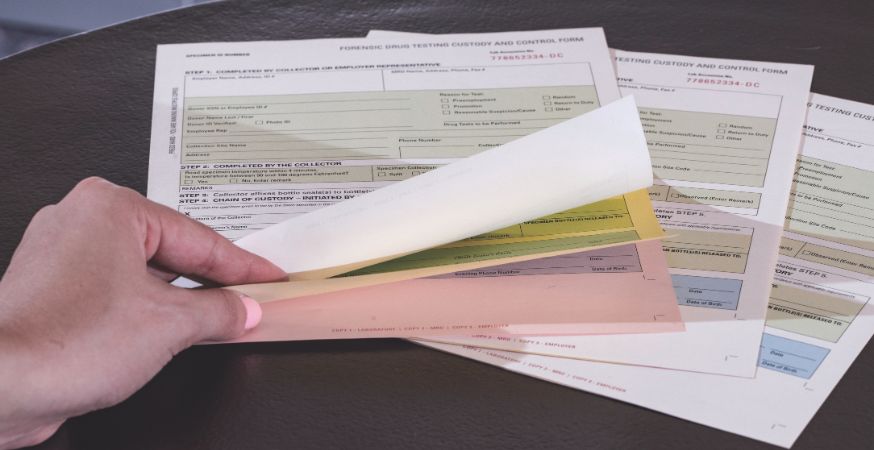

Each sheet in a carbonless set plays a specific role:

- CB (Coated Back): The top sheet, coated on the back with tiny dye capsules.

- CFB (Coated Front and Back): The middle sheet, which carries dye on the back and a reactive clay on the front.

- CF (Coated Front): The final sheet, which holds only the clay coating.

When you write or print on the top sheet, pressure from your pen or printer ruptures the microcapsules. The released dye reacts with the clay on the sheet below, forming a clean, legible image. This chain reaction continues through all parts of the set, producing clear copies on every page without the need for carbon film or secondary printing.

Straight vs. Reverse Sequence: What’s the Difference?

This is where things often get confusing, especially when loading paper into different printer types.

Cover Stock or Card Stock

In a straight sequence set, the sheets are arranged in standard order: White (top) → Canary (middle) → Pink (bottom).

This layout is best for:

- Top-feed printers (where paper is pulled from the top of the tray)

- Handwritten forms or manual filling

Straight sequence ensures that the white original stays on top as you print or write, followed by the yellow and pink copies in the correct order.

Reverse Sequence (Reverse Collated)

Reverse sequence flips the order: Pink (top) → Canary (middle) → White (bottom).

This version is ideal for:

- Bottom-feed printers (where paper feeds upward from the bottom of the tray)

- High-speed digital printers or copiers that output pages face-down

In this setup, even though the printer processes pages in reverse, they’ll exit the machine correctly stacked with the white copy on top, ready for padding, stapling, or distribution.

Getting this right ensures your forms print in the proper order every time, saving time, paper, and frustration.

Understanding Carbonless Paper Types

Beyond sequence, carbonless papers differ by weight, ply count, and coating:

- Ply count: Two-part, three-part, four-part, and five-part sets are available, depending on how many copies you need.

- Weight: Typically ranges from 15 lb to 21 lb, lighter for handwritten forms and heavier for use in high-speed laser or impact printers.

- Finish: Smooth coatings for clean printing, or slightly textured options for easy handwriting.

Brands, such as Nekoosa, also offer carbonless paper with recycled content, providing a sustainable option for eco-conscious businesses.

Tips for Printing and Padding Carbonless Sets

Once you’ve chosen the right sequence, a few practical techniques can help ensure clean, professional results:

- Check your printer’s feed direction before loading paper to determine whether you need straight or reverse sequence.

- Fan the sheets lightly to reduce static and prevent sticking.

- Avoid excessive heat settings that could damage the microcapsule coating.

- Store paper in a cool, dry environment to preserve sensitivity and image clarity.

If you’re padding your own carbonless forms, Nekoosa NCR padding adhesive makes the process simple. Apply a thin layer along one edge of your collated stack, let it dry, and fan apart your finished pads for easy use. The result is clean, tear-resistant forms that hold together securely until you’re ready to separate them.

Choosing with Confidence

Both reverse and straight sequence carbonless papers are designed for efficiency; it’s simply a matter of matching the sequence to your printer and workflow.

- Straight sequence: Best for top-feed printers and manual form use.

- Reverse sequence: Perfect for bottom-feed printers and automated setups.

With the right paper and adhesive, you can produce crisp, durable, and professional-looking forms that support smooth operations in the office, classroom, or print shop.

Stock up on Nekoosa carbonless papers to keep your forms printing cleanly and efficiently every time.